To set up a water bottling factory, you will need to consider the following steps:

- Determine the scale of the factory: Consider the volume of water you want to produce, the size and type of bottles you will be using, and the type of production process you will use.

- Choose a location: Select a suitable location for the factory, taking into consideration factors such as access to raw materials, transportation, and utilities.

- Obtain necessary permits and licenses: Obtain the necessary permits and licenses for the construction and operation of the factory, including any environmental and health and safety regulations.

- Design the factory layout: Design the layout of the factory to optimize the production process and ensure efficient flow of materials and products.

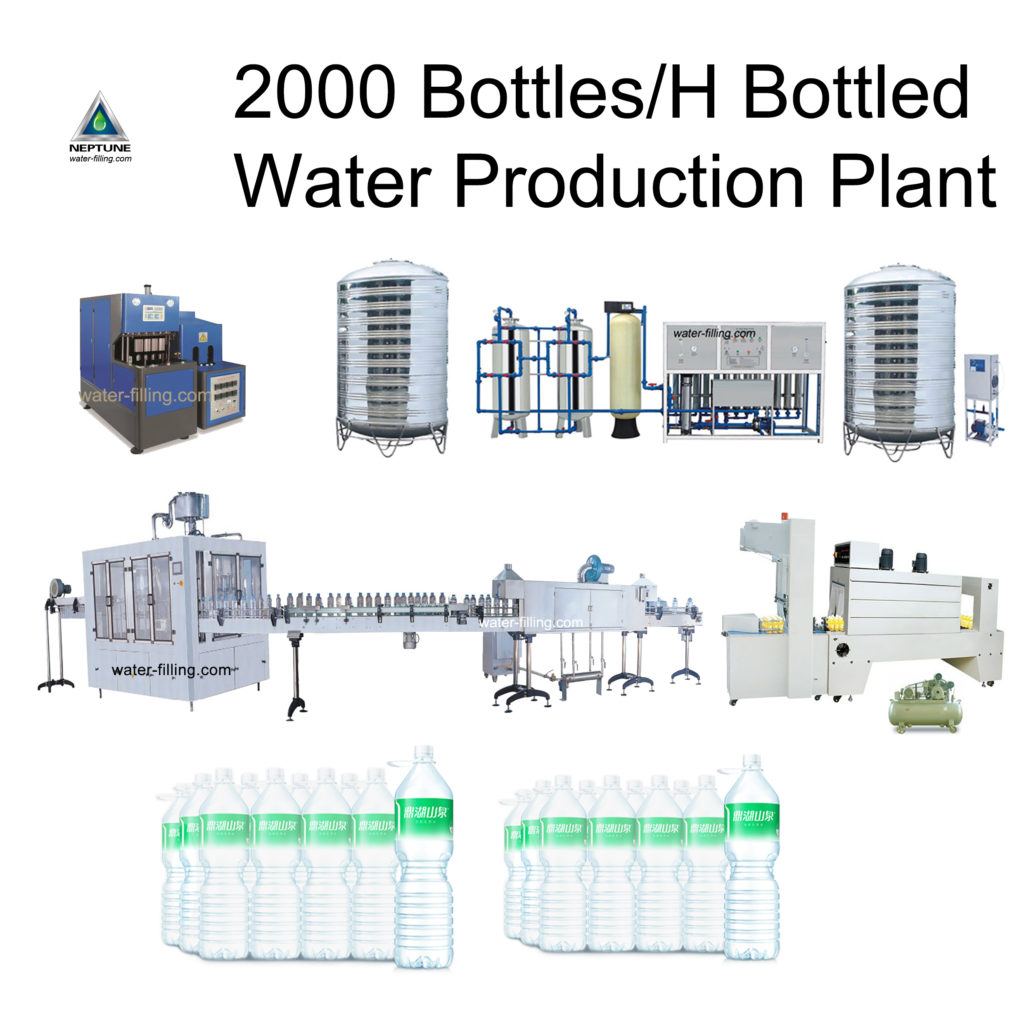

- Procure equipment and machinery: Purchase the necessary equipment and machinery for the production of bottled water, including bottle blow molding machines, filling and capping machines, and labeling and packaging equipment.

- Establish a water treatment system: Set up a water treatment system to ensure the quality and purity of the water used in the production process.

- Implement quality control measures: Implement measures to ensure that the bottled water meets all relevant regulations and standards for quality and safety.

- Train employees: Develop a training program for employees to ensure that they are properly trained in the operation of the equipment and the production process.

- Establish a maintenance program: Set up a program to ensure that the equipment is properly maintained and any necessary repairs are carried out in a timely manner.

By following these steps, you can successfully set up a water bottling factory that produces high-quality bottled water that meets all relevant regulations and standards.

13 reasons to invest in bottle water business in 2023

Here are 13 reasons why investing in a bottled water business in 2023 may be a good idea:

- Growing demand for clean drinking water: As the global population continues to grow, the demand for clean, safe drinking water is also increasing. Bottled water provides a convenient and portable way for people to access clean drinking water, especially in areas where the public water supply is unreliable or unavailable.

- Improved water quality: Bottled water is typically purified and treated to remove contaminants and improve the taste and quality of the water. This can provide customers with water that is safer and more pleasant to drink than the water from the public supply.

- Greater convenience: Bottled water is easy to transport and can be consumed on-the-go, providing customers with a convenient way to stay hydrated and healthy. This can be especially useful in areas where the public water supply is contaminated or unsafe to drink.

- Cost savings: In some cases, bottled water may be more cost-effective than purchasing bottled water. By bottling water in bulk and selling it to customers, you can reduce the cost of bottled water and provide customers with a more affordable option.

- Potential for high profits: The bottled water industry is a multi-billion dollar industry, and there is potential for high profits for businesses that produce and sell high-quality bottled water. With the right marketing and distribution strategy, a bottled water business can generate significant revenue.

- Environmentally friendly: By using recyclable bottles and eco-friendly packaging, a bottled water business can help reduce the environmental impact of bottled water. This can help improve the sustainability of the bottled water industry and support efforts to protect the environment.

- Easy to operate: Bottling and selling water is a relatively simple and straightforward business venture. With the right equipment and expertise, a bottled water business can be easily set up and operated.

- Potential for expansion: The bottled water industry is global, and there is potential for a bottled water business to expand and grow beyond its local market. With the right business strategy, a bottled water business can enter new markets and increase its revenue and profitability.

- Low overhead costs: Compared to other types of businesses, a bottled water business has relatively low overhead costs. The main costs are the cost of water, bottles, labels, and packaging materials, as well as the cost of labor and transportation.

- High demand for premium bottled water: In addition to standard bottled water, there is also a growing demand for premium bottled water. This includes bottled water from natural sources, such as springs and wells, as well as bottled water with added minerals and other ingredients. A bottled water business can capitalize on this trend by offering premium bottled water options to customers.

- Opportunities for product diversification: In addition to bottled water, a bottled water business can also offer other related products, such as reusable water bottles, water filters, and water dispensers. This can help increase revenue and diversify the business.

- Support for local communities: A bottled water business can provide employment and support for local communities. By sourcing water from local sources and hiring local workers, a bottled water business can help stimulate the local economy and support the growth of the community.

- Positive impact on public health: By providing access to clean, safe drinking water, a bottled water business can have a positive impact on public health. This can help reduce the incidence of waterborne diseases and improve the overall health and well-being of the community.

Overall, investing in a bottled water business in 2023 can provide a profitable and sustainable business venture that can help meet the growing demand for clean drinking water and support the local community.

location and Factory Workshop

how to choice location of water bottling workshop

There are several factors to consider when choosing the location for a water bottling workshop:

- Access to raw materials: The workshop should be located near a source of clean and pure water, as this is the main raw material for water bottling.

- Transportation: The workshop should be located in an area with good transportation infrastructure, as this will make it easier to transport raw materials and finished products.

- Utilities: The workshop should have access to reliable utilities, including electricity, water, and gas, to ensure smooth operation.

- Labor: The workshop should be located in an area with a sufficient labor pool to support the production process.

- Market: The workshop should be located in an area with a sufficient demand for the products being produced.

- Regulations: The workshop should be located in an area where the necessary permits and licenses can be obtained and where all relevant regulations and standards are met.

It is important to carefully assess these factors and consider the specific needs of your business when choosing the location for a water bottling workshop.

how to build Aseptic water bottle production workshop

To build an aseptic water bottle production workshop, you will need to consider the following steps:

- Determine the production capacity and size of the workshop based on your business needs.

- Select a suitable location for the workshop, taking into consideration factors such as access to raw materials, transportation, and utilities.

- Design the workshop layout to optimize the production process and ensure efficient flow of materials and products.

- Obtain the necessary permits and licenses for the construction and operation of the workshop.

- Procure the necessary equipment and machinery for the production of aseptic water bottles, including bottle blow molding machines, filling and capping machines, and labeling and packaging equipment.

- Establish a water treatment system to ensure the quality and purity of the water used in the production process.

- Implement quality control measures to ensure that the bottles are produced to the required standards of quality and safety.

- Develop a training program for employees to ensure that they are properly trained in the operation of the equipment and the production process.

- Establish a maintenance program to ensure that the equipment is properly maintained and any necessary repairs are carried out in a timely manner.

- Set up a system for monitoring and controlling the production process to ensure that it is operating efficiently and producing high-quality products.

It is important to follow all relevant regulations and standards when building and operating an aseptic water bottle production workshop to ensure that the products produced are safe for consumption.

Buy water bottling machine production

To buy a water bottling machine for production, you will need to consider the following steps:

- Determine your production needs: Consider the volume of water that you need to produce, the size and type of bottles you will be using, and any additional features or capabilities that you may require.

- Research suppliers: Look for suppliers that offer the type of water bottling machine that meets your production needs. You can search online or ask for recommendations from other industry professionals.

- Request quotes: Contact the suppliers and request quotes for the water bottling machine. Be sure to provide them with all of the relevant details about your production needs, such as the volume of water you need to produce and the size and type of bottles you will be using.

- Compare quotes: Compare the quotes you receive from different suppliers to determine the best price and value.

- Evaluate the supplier: Consider the reputation and experience of the supplier, as well as any warranties or after-sales support they offer.

- Place the order: Once you have selected the supplier that best meets your needs, place the order for the water bottling machine.

By following these steps, you can buy a water bottling machine that meets your production needs and budget. It is important to carefully research and evaluate different suppliers to ensure that you are purchasing a high-quality machine that will meet your production needs.

materials

The materials needed for the production of bottle water include:

1. pE water cap

PE (polyethylene) water caps are caps made from polyethylene plastic that are used to seal water bottles. These caps are commonly used in the production of bottled water, as they provide a secure seal that helps to preserve the quality and purity of the water.

PE water caps are available in various sizes and styles to fit different types of bottles. They can be made by injection molding, in which molten polyethylene plastic is injected into a mold to create the desired shape, or by blow molding, in which a preform is heated and blown into the shape of the cap using air pressure.

PE water caps are lightweight, durable, and inexpensive, making them a popular choice for water bottle producers. They are also easy to open and close, which makes them convenient for consumers. In addition, PE water caps are resistant to moisture, which helps to prevent leaks and spills.

2. pET water Preform

PET Preform is a small, tube-like piece of plastic that is used to make bottles. It is typically made from a type of plastic called polyethylene terephthalate (PET). Preforms are used in the process of blow molding, in which they are heated and blown into the shape of a bottle using air pressure.

Preforms are commonly used in the production of water bottles, as well as other products such as soda bottles, juice bottles, and food containers. They are typically made by injection molding, in which molten plastic is injected into a mold to create the desired shape. Preforms can be made in various sizes and shapes to meet the needs of different products.

3. pVC Sleeve Label

Labels: Bottle water is typically labeled with information such as the brand name, type of water, and volume. These labels are made from paper or plastic and are applied to the bottles using adhesives.

4. PE wrap film

PE wrapping packaging materials: Bottle water is often packaged by wrapping pe film for shipping and storage.

It is not only cheap but also anti-rain.

How to selling bottle water

how to Promote your bottle water brand

There are several strategies you can use to promote your bottle water brand:

- Develop a strong brand identity: Create a unique and memorable brand identity that reflects the values and benefits of your water. This can include a logo, color scheme, and packaging design.

- Create a website and social media presence: Establish a strong online presence through a website and social media platforms. This will allow you to reach a wider audience and engage with customers.

- Use traditional marketing methods: Utilize traditional marketing methods such as print and radio advertising, as well as direct mail and billboards, to reach potential customers.

- Partner with local businesses and events: Partner with local businesses and events to promote your brand and reach a targeted audience.

- Offer promotions and discounts: Offer promotions and discounts to encourage customers to try your brand and encourage repeat purchases.

- Provide excellent customer service: Provide excellent customer service to encourage customer loyalty and positive word-of-mouth promotion.

- Use packaging to differentiate your brand: Use packaging to differentiate your brand and make it stand out on store shelves.

By implementing a combination of these strategies, you can effectively promote your bottle water brand and increase its visibility and sales.

how to wholesale bottle water

To wholesale bottle water, you can follow these steps:

- Determine your target market: Identify the type of businesses or organizations that you want to sell your water to, such as restaurants, cafes, office buildings, or event venues.

- Develop a pricing strategy: Determine the price at which you will sell your water in bulk, taking into account the costs of production, packaging, and transportation.

- Create a sales pitch: Develop a sales pitch that highlights the benefits of your water, such as its purity, taste, and any unique features it may have.

- Create a list of potential customers: Identify potential customers in your target market and create a list of their contact information.

- Reach out to potential customers: Contact potential customers through email, phone, or in-person meetings to pitch your water and discuss potential wholesale orders.

- Negotiate terms and finalize the sale: Once you have received an order, negotiate the terms of the sale, including the price, quantity, delivery dates, and payment terms.

- Fulfill the order: Once the sale has been finalized, prepare the order for shipment or delivery and ensure that it is delivered on time and in good condition.

By following these steps, you can successfully wholesale bottle water to businesses and organizations in your target market.