Complete 5 gallon water bottling machine plant from A to Z for refill 3 gallon to 6 gallon bottled water. Factory directly selling at the lowest price.

It is an mineral water production plant which use to produce 3gallon 5gallon & 6gallon bottled water. The bottle is reused and every time need brusher ouside and inside washing, city water push washing and pure water washin to make sure the bottle clean.

5 Gallon Production Plant Price List

200Bottles/H Plant $13,430

Complete 5 gallon 200bottles/h water bottling plant for sales

300Bottles/H Plant $14,640

Total cost of the 300 bottles/h 5 gallon filling plant

450Bottles/H Plant $19,770

The price of an 450 bottles/h 5 gallon jar water filling plant

It included capper removed machine, leak check machine, brusher washing outside and inside machine, push washing and filling capping machine, mouth sealing machine.

5 Gallon Water Packing Machinery Price List

Cap Pulled Machine

Automatic removed the cap of got back bottle. With 2m conveyor belt

200 Bottles/H $ 1580

300 Bottles/H $ 1580

450 Bottles/H $ 1920

Outside and Inside Brush Machine

Automatic brush washing outside and inside of the bottle. With 2m conveyor belt

200 Bottles/H $ 4680

300 Bottles/H $ 4680

450 Bottles/H $ 5350

Bottle Loading Machine

Turn the bottle 180 degree to loading the filling machine. With 2m conveyor belt.

200 Bottles/H $ 1500

300 Bottles/H $ 1500

450 Bottles/H $ 1840

Cap Washing and Loading Machine

Automatic washing the plastis cap with ozone water. Then loading to the filling machine

200 Bottles/H $ 1500

300 Bottles/H $ 1500

450 Bottles/H $ 1640

5 Gallon Water Filling Machine

Push washing bottle with NaOH and water. Filler water into bottle and capper well.

200 Bottles/H $ 3170

300 Bottles/H $ 4380

450 Bottles/H $ 7770

Steam Mouth Sealing Machine

Bottle with film mouth shrink sealing. Come with 2m conveyor belt.

200 Bottles/H $ 1000

300 Bottles/H $ 1000

450 Bottles/H $ 1250

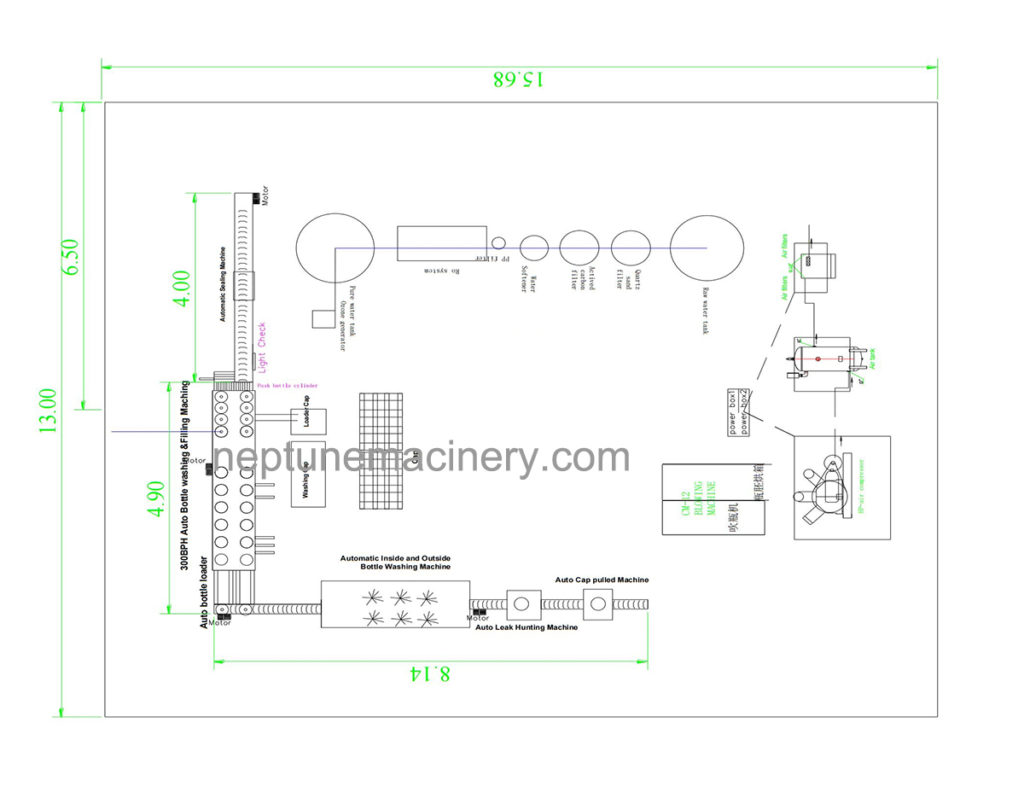

Layout Of 5 Gallon Water Bottling Machine Factory

- All parts contacting water are made of 304L stainless steel with ozone-resistance and in compliance with food-grade standards.

- Nozzles are inserted to rinse the bottles thoroughly.

- Fast cycle system is adopted for heated alkali rinsing, drastically decreasing electricity consumption.

- Controlled by PLC, it is fully automatic.

Feature of 5 gallon water bottling machine plant

All line controlled by PLC, the water bottling machine integrates the functions of 3/5 gallon bottle washing, filling and capping on one set of machine.

It is manufactured in compliance with the standard of China Purified Water Industry Association, and with reference to overseas newest type of machine

It not only have advanced technology, high automatically, easy operation and reliable performance, but also small size, small weight and beautiful appearance, anti-corrodibility, thorough disinfection, effective antipollution and high quality. The device employs key components of electrical appliances and metal materials manufactured by brand factories at China and abroad. Nonmetallic components are manufactured elaborately by wearable materials, such as nontoxic PP plastic, etc.

Process of production plant

- Removed the cap

- Leak check

- Brush washing the outside and inside of the bottle

- Automatic turn 180degree loading

- NaOH and pure water push washing

- Auto filling and pressure capping

- Cap washing and loading

- Mouth an label sealing the bottled water

FAQ

How Profit Of An 5 Gallon Bottle Water Business?

Bottled is reused. Cap and water materials cost lesst than USD 0.2

An 20liter bottled water wholesales price ranging from 1dollar to 4dollar. Most usually sales at 2dollar.

Worker dilivery 1psc 20l bottled water to customer salary is USD 0.3

So that 1psc 20l bottled water gross profit is USD 1.5. And per day 1600bottles. It can profit USD 2400 per day. Any customer not only working time need drinking pure water but also holiday need drinking pure water. One year it can profit about USD 87600

Why 5 Gallon Bottled Water Business usually do not have agent?

A 5gallon bottled water weight 20kg, so that dilivery to customer is an hard work.

A big cost of 5gallon bottled water business is dilivery the bottled water to consumer home or office.

Most factory running the 5gallon business by themseleves without channel or agent. Because a factory everyday just produce 1600bottles. And every bottle is heavy, so that factory mostly builded closed to the city or town. Means factory closed to the customer.

Factory running sales and dilivery themselves is this business natural features.

Why Still Now Have Chance To Setup An 5 Gallon Water Bottling Machine Plant ?

The world most big profit business is been hold by big brand. But for 5gallon safe drinking water. Every bottle is heavy. Dilivery cost big and take time. Fresh safe pure water is love by customer. Some small town and city population is not very big. So that big brand no willing to build an factory there. For big branch, even an manager salary is over hundreds thousand dollar.

And small city and town, not only salary will increase, but also population will increase. So that safe water inquiry will increase.

How Can Neptune Machinery Help?

We will assist you with establishing your 5gallon bottled purified water plant from the conception of the idea to when you are ready to open your plant.

Please call or email us to find out more on this profitable business and to see how Neptune Machinery can help you start your operation. 5Gallon bottle water plant also need Pure water supply which most use reverse osmosis water treatment machine and bottle blow molding machine.

What is the Benefits of 5 gallon pure bottle water business:

Good way to bottling water for university

Can be very profitable; especially in large volume.

The 5gallon bottles can reuse for 2year.

Much better use of plant space as the units are compact.

Environmentally friendly, No pollution at all.

Much lower cost to set up plant.

Street sellers will sell to create jobs.

Why there are a lot washing machine and washing process in an 5 gallon water bottling plant?

5 gallon bottle is reuse. it is environmentally friendly and not pollution at all. Of course, the most import step of refill process is not filler but the washing. It not only need outside and insider brusher washing to make sure reuse bottle clean. But also need medicine washing for make sure no any chemical pollution the bottle. Then it is pure water washing , filling and capping process.