FOB Price 38,350.00

What this price included?

| 4Cavity Automatic Blow Molding Machine |

| Preform unscrambler |

| HP Air Compressor 2.4m3/min ,30Kg |

| LP Air Compressor 2.0m3/min ,10Kg |

| Air Dryer(inside 2 Air filters) 2.0m3/min ,30Kg |

| Air Tank 0.6m3 30Kg |

| Mould Chiller3HP |

| High-low pressure tracheal connection |

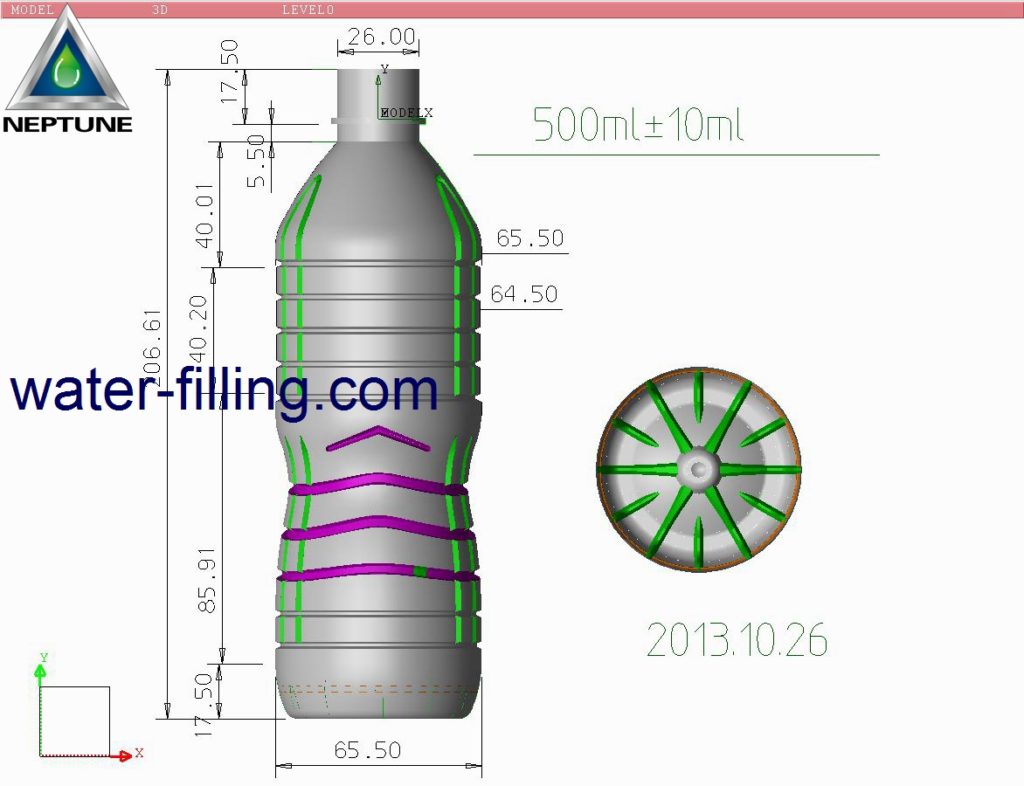

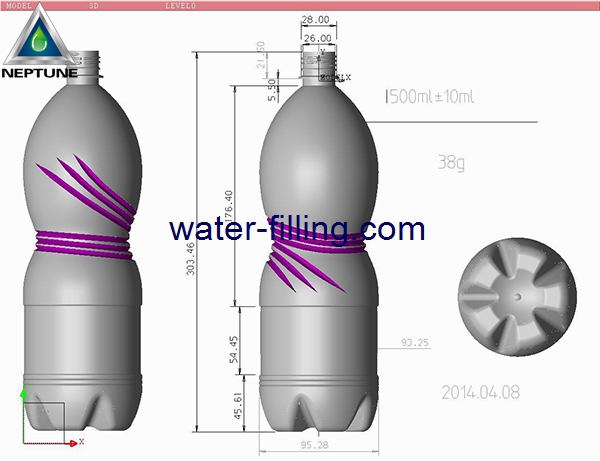

| Blow Mold (500ml) Four cavity |

Automatic 4 cavity pet bottle blow molding machine through a certain process blow the pet preform into plastic pet bottles. It mainly used to produce the carbonated bottle, mineral water bottle, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle and so on.

- Control by PLC, touch screen easy opretion

- Fully automatic from loading preform to outlet plastic bottle.

- Fast and friendly use, 4000 bottles per hour depend on 500ml bottle

- All-inclusive solution, install and production without extra equipment

| Capacity of production | 4000PCS/H |

| Bottle volume | 100ml to 2000ml |

| Neck diameter | 15mm-38mm |

| Cavity | 4cavities |

| Mold thick | 240mm |

| Mold | 500*500mm |

| Electrical source power | 380v 3Phase /220v 3Phase 50/60HZ |

| Rated Power | 49kw |

| Really use power | 10kw |

| LP air compressor | 2.0m3/min 1.0MPa |

| HP air compressor | 2.4m3/min 3.0MPa |

| Air dryer | 2.0m3/min 3.0MPa 1set |

| Cooling water | 15L/min |

| Blower Main Machine L*W*H | 1908*1858*1920mm |

| Blower Main Machine Weight | 3600kg |

| Preform loader L*W*H | 276*106*186mm |

| Preform loader Weight | 250kg |

| Resin available | PET |

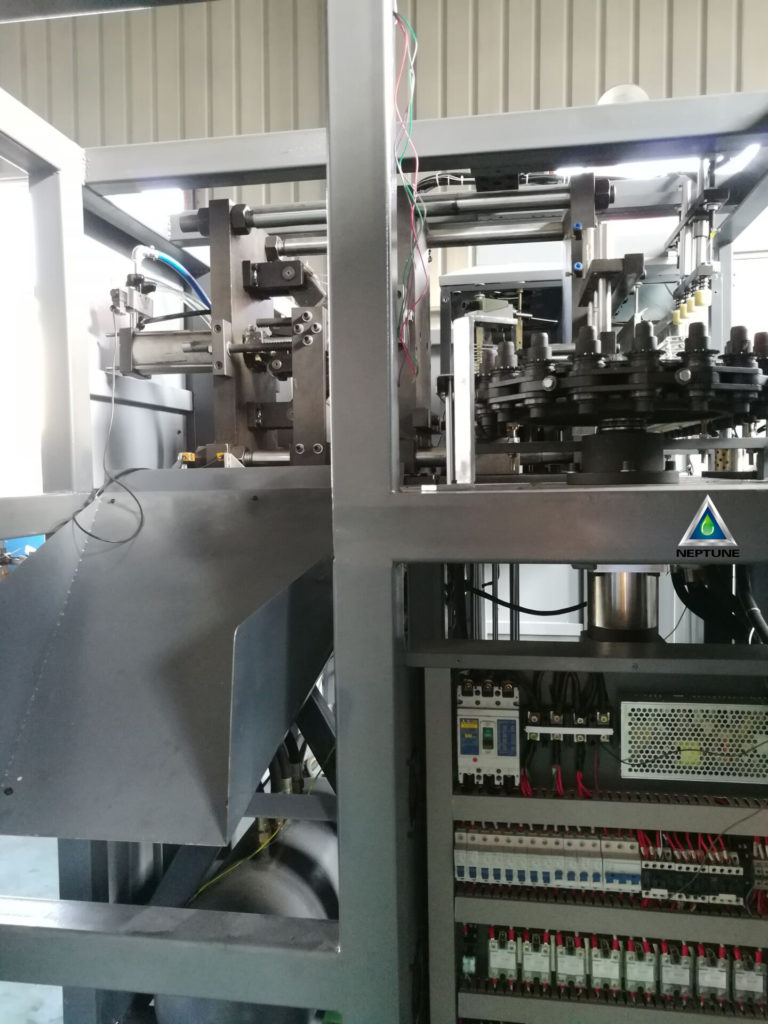

Video of the 4 cavity automatic bottle blow molding Machine

It the second step of the pet bottle blow molding machine. The first is injection plastic preform.

Less than 5% bottled water company will produce preform by themselves. Because the pet preform is closed to oil industry. It is very low gross and occupy bottled water company cash flow. Leave it to professional preform factory will be better.

Why Most Bottled Water Company Produce Plastic Water Bottle Themselves?

- The most import is the empty take room. Freight will cost big

- Empty bottle will easy crushed if stacked, its inside without anything

- The empty plastic bottle will been pollution if long time touch air

- The plastic bottle making process need heating the preform into high temperature, So that produce out plastic bottle is sterile. Fast finished bottling and sealling. Reduce touch air

- Famous bottled water company usually have an unique bottle design. It can protect their brand

- In long time it is save the cost

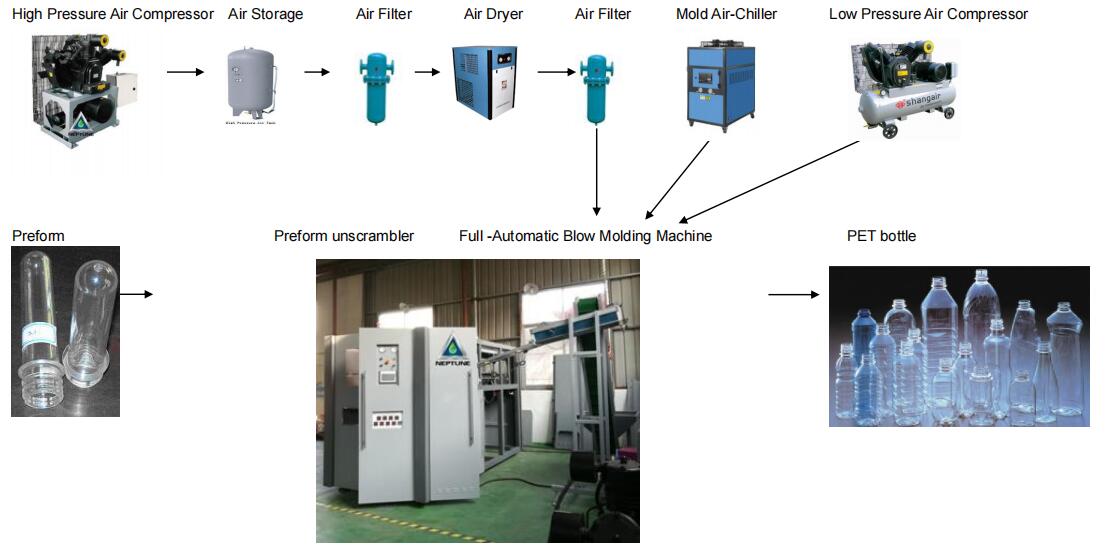

How Does 4 Cavity Pet Bottle Blowing Machine It Work?

- Preforms unscrambler will automatic load the preform.

2. Machinery gear will transfers the preform to the heating oven

3. 10psc infrared lamps can be adjusted individually to control the temperature of oven. Preform automatically rotate can make sure preform heating evenly. The infrared thermometer inspecting temperature and will automatic adjust it by itself. All parameter can saw in the touch screen of the Neptune automatic blow molding machine and can easy setting. So that can always fit the best heating temperature

4. The temperature sensor can inspectst the temperature of the preforms. According compare with preset data, it will automatic feedback data to oven, and Oven will automatic adjust the temperature to the necessary temperature.

5. Preforms star-wheel will automatic transfer the after heated preform to the blow mold.

6. First, the preform will stretched in the mold. And then will blow into shape plastic bottle by high pressure air.

7. Machinery gear will transfers the plastic bottle to the air conveyor belt.

8. Air conveyor belt will directly send plastic bottle to washing filling capping machine.

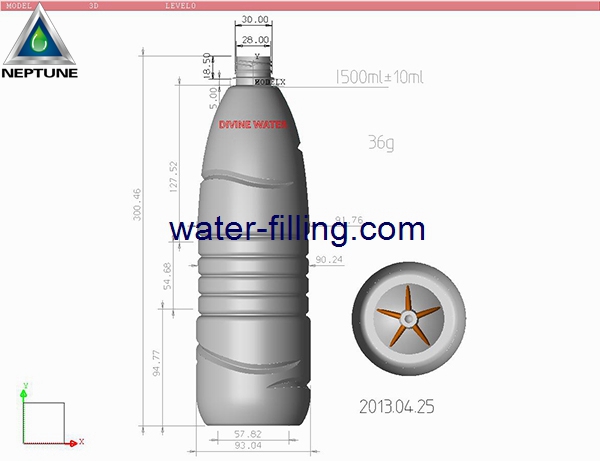

Choice an bottle design as mold

An good bottle design will effect an bottled water company business. It is very important. Neptune have professional bottle design machine and experienced. Make sure final produce out bottle is completely same with bottle design. And bottle will have good quality. Make sure bottle mark clear and standing stable. Good structure bottle will standing stable. Then producing conveyor well. And final putting in shop and shelf is good