Fob Price $ 11,000.00

What this price inlcuded?

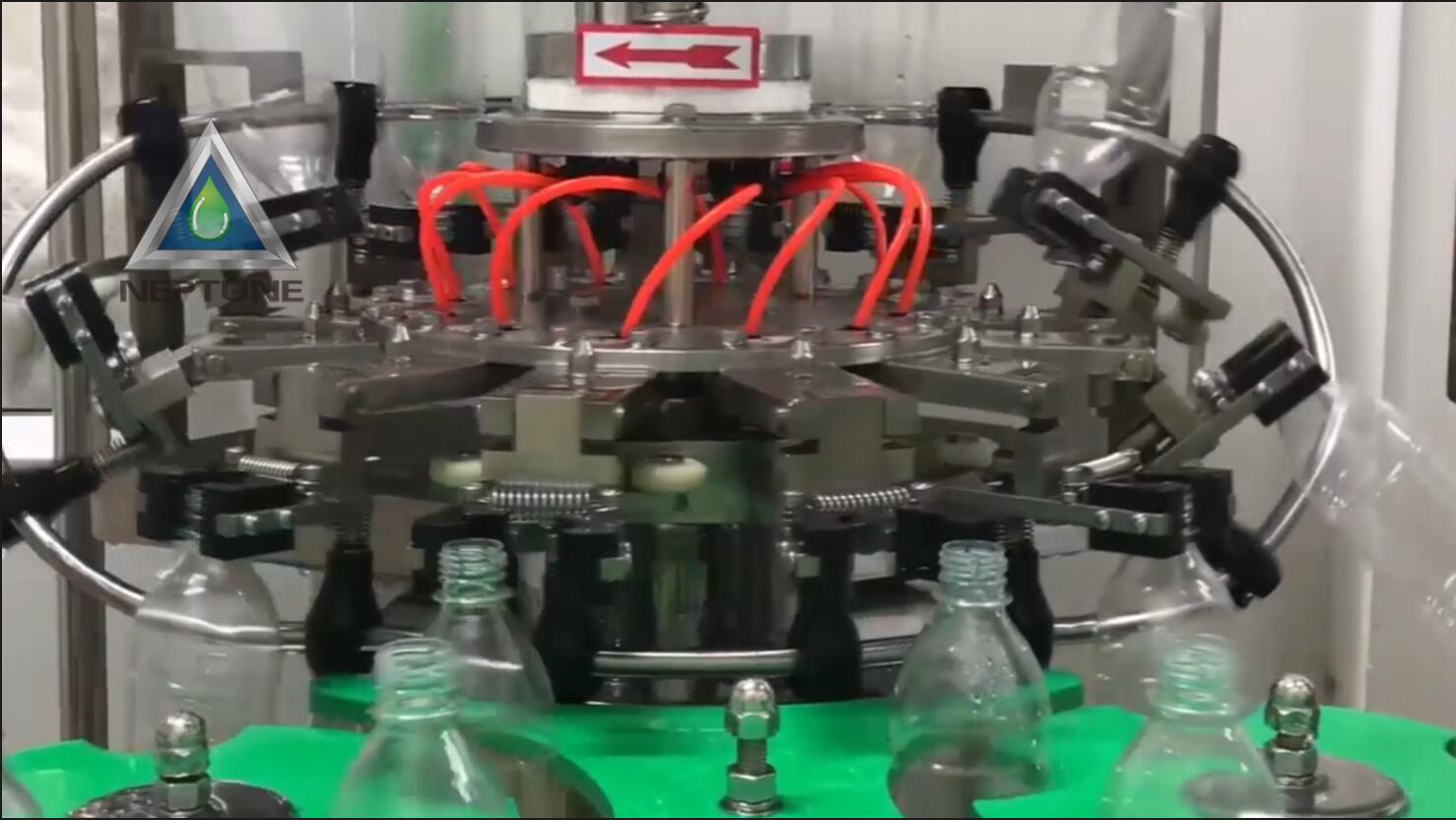

- 12 Head Washing Machine

- 12 Head Filling Machine

- 1 Head Capping Machine

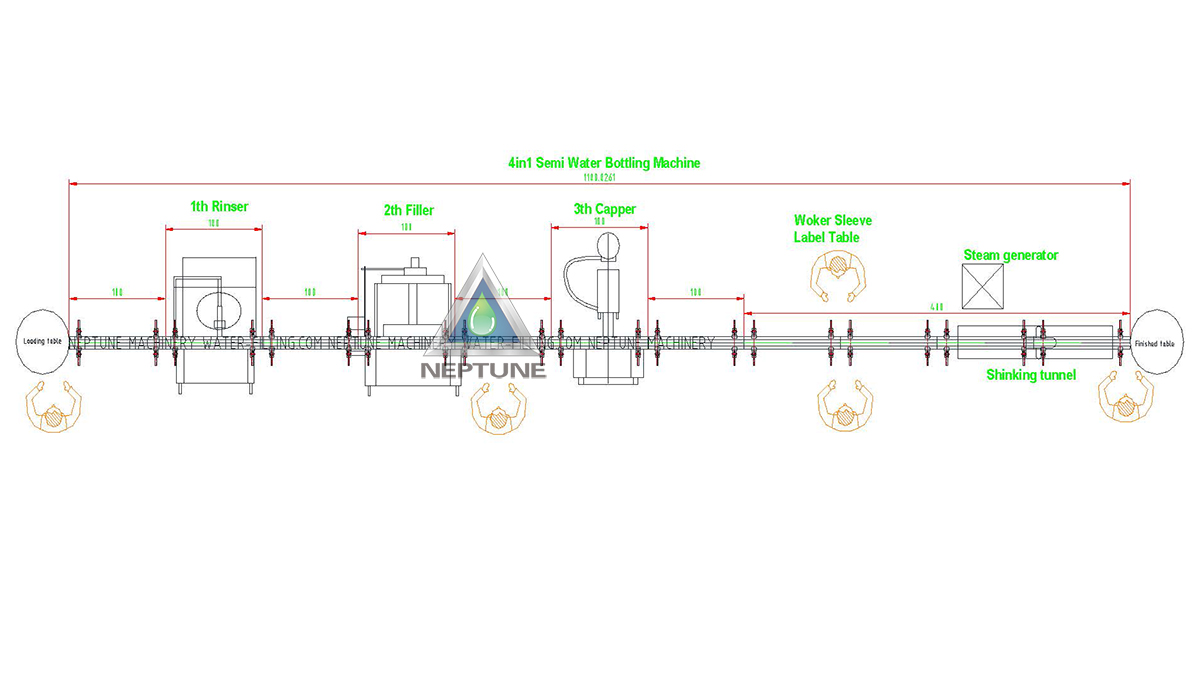

- 11 Meter Conveyor Belt

- 1 Set Motor

- 1 Set Steam Generator

- 1 Set Shrink Tunnel

- 2 Set Working Table

4in1 Semi Bottling is a commercial semiaumatic water bottling machine used for washing, filling, capping and labeling any bottle range from 200ml to 2 liters. The 4in1 semi bottling water station is most usually used for 500ml and 1.5liter bottles water. It is popular worldwide. Especially in Africa, South America, Middle East and Southeast Asia

- Included rinser, filler, capper and labeler

- High efficacy and cost effective in low labor cost areas.

- It has been proven to be fast and stable in a variety of applications.

- 2000 bottles per hour depend on 500ml bottle with

- 4 labor workers tending to the bottling line

parameter

| Capacity Production | 2000 Bottles/H |

| Bottling Volume | 200ml-2000ml |

| Packaging Type | Bottles |

| Driven Type | Motor |

| Machine Weight | 1200kgs |

| Machine Dimension(mm) | 11000*1200*1200 |

Can i bottle my own water and sell it?

It is generally possible to bottle your own water and sell it, but there are certain regulations and requirements that you will need to follow in order to do so safely and legally. These may vary depending on your location, but in general, you will need to:

- Obtain necessary licenses and approvals: You will need to obtain the necessary licenses and approvals from the local authorities to operate a water bottling business. This may include a food safety license, a trade license, and an environmental permit.

- Ensure the quality of the water: It is important to ensure that the water you are bottling is safe and of high quality. This may involve testing the water for contaminants and impurities, and treating it appropriately if necessary.

- Follow proper bottling and packaging procedures: You will need to follow proper bottling and packaging procedures to ensure that the water is sealed and stored safely. This may involve using sterilized equipment and containers, and following good manufacturing practices.

- Follow labeling requirements: You will need to follow labeling requirements for bottled water, which may include providing information about the source of the water, the treatment it has undergone, and any additives or contaminants it may contain.

It is important to research the specific regulations and requirements that apply to your location and ensure that you are complying with them when bottling and selling water. Failure to do so could result in legal consequences and damage to your reputation.

1th auto Rotary Rinser

The semiautomatic water bottling station is capable of continued washing 12 bottles at an 360 degree disk while moving the bottle to next process. You can use ozone water for washing the bottle so that rinse and sanitize at the same time.

2th auto Rotary Filler

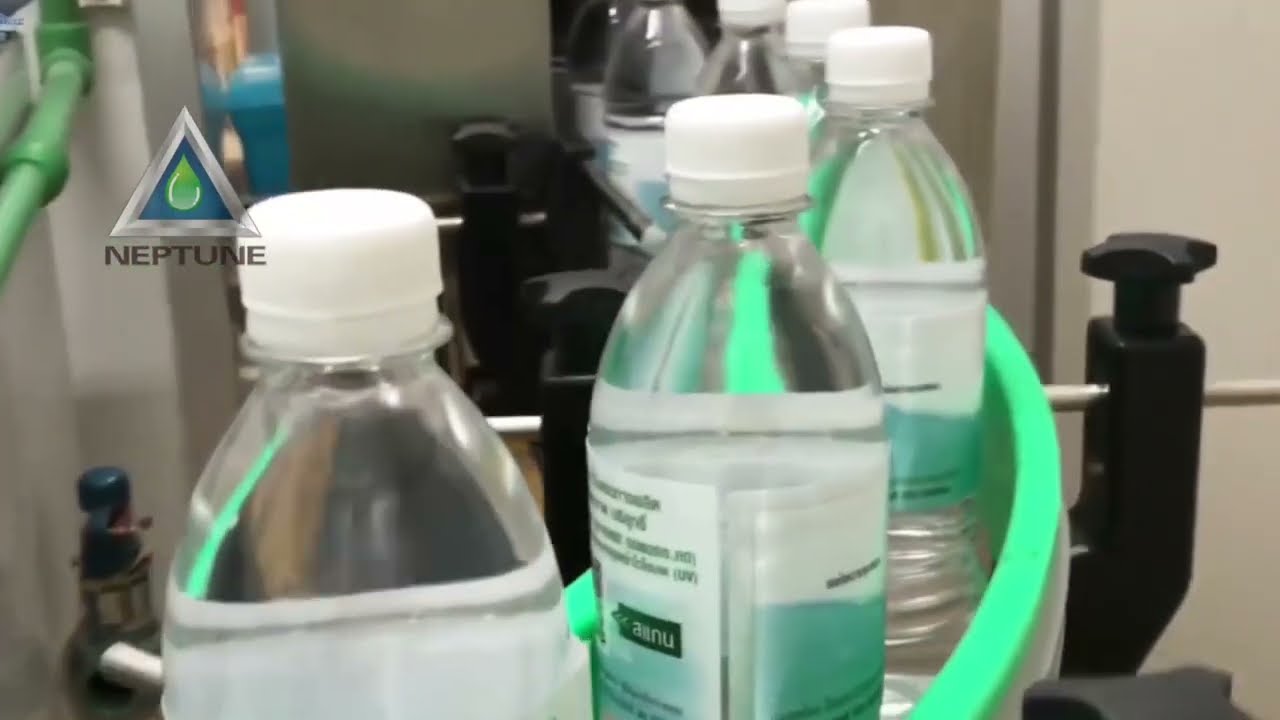

The 4in1 semi water bottling machine filling head(nozzles) moving together with bottle while filling water into the bottle. The bottle moving on a 360 degree disk with 12 station hold 12psc bottle water.

3th auto Screw Capper

The 4in1 semi water bottling machine capping way is screw cap. It fixed the cap box on the top of the capper machine and automatic feeding the cap on every bottle water. The bottle water been catch by neck on the solt so that not easy move and fall the cap. And solt moving to screw cap. It is the most advanced capping way.

4th Semi Sleeve Labler

4in1 Semi automatic water bottling machine features a very friendly, trouble-free due to its effective design. Auto rinser filler capper with a semi labler. The loading empty bottle and sleeve label is semiautomatic. The unique design of the Easy Fill allow it to be very energy efficient compared to other water bottle filling machines.

11 meter long, 4in1 semi Automatic water bottling Machine

4in1 Semi automatic water bottling machine from beginning to the end long is 11meter. It can be setting more short or L shaped according to your factory room.

The 4in1 semi bottling can be used to fill any bottle water range from 7 oz to 70 oz. It can easily interfaced with any of our water purification or water purifier machine.

Video of the 4in1 semi Automatic water bottling Machine

The 4in1 semi water bottling machine included a washing, filling, capping and labeling system which allowing you to rinser, filler, capper and labler bottle water all in one simple and trouble free machine.

certificate

4in1 semiautomatic water bottling machine manufactured in the China with ISO9001 and got CE certificate to ensure a very high quality and stable.

Warranty

4in1 bottled water filling machine warranty 1 year on parts due to manufacturer defect and included free online technical support. Also support engineer oversea installation but need buyer pay engineer cost.