FOB Price 33,240.00

This plastic water pet bottle blowing machine have two caivty. Its capacity of production are 2000 bottles per hour. Most usually use to produce mineral water bottle and pure water bottle.

Also, the pet bottle blow moulding machine can use to produce some juice and carbonated drink bottle. What’s more, it only change mold and some spare part to produce different volume and shape bottle. But it only can produce 200ml to 2000ml plastic bottle.

Main technical specifications

1. Production capacity: 2000 bottles per hour depend on 500ml bottle

2. Bottle blowing height: 50-350 mm

3. Max. mould thickness:240mm

4. Machine capacity:25KW

5. Power: 6-14 KW

6. Power source: 380V 3-phase /220 V 3-phase 50/60Hz

7. Working pressure: 0.7-0.9Mpa

8. Blowing pressure: 1.6-4.0Mpa

9. Overall dimension: 1908mm(L) × 1280mm(W) × 1800mm(H)

Advanced High Quality Pet Bottle Blowing Machine

It is widely applied in blowing hollow plastic containers of various dimensions. They are characterized by stable quality of products, reasonable design of structure of machines, small size, low energy consumption, easy operation and convenient maintenance. All spare parts of two cavity automatic blow moulding machines are treated by high and new technologies, precise machining and careful assembly to attain technical requirements of all aspects. Moving parts are connected with boundary lubricating bearings and straight guide rails( guiding blocks are made in Japan). Japanese made bumper is adopted for preventing mechanical bumping, which ensures low mechanical noise, low failure rate and long service life. Moreover, unique design of air blowing mechanism ensures very high output rate of finished products. The operation of two cavity automatic bottle blowing machinery are computer controlled, which ensures accurate and reliable operation. Individualized operations and operation monitoring of the machine are realized by human-machine interface.

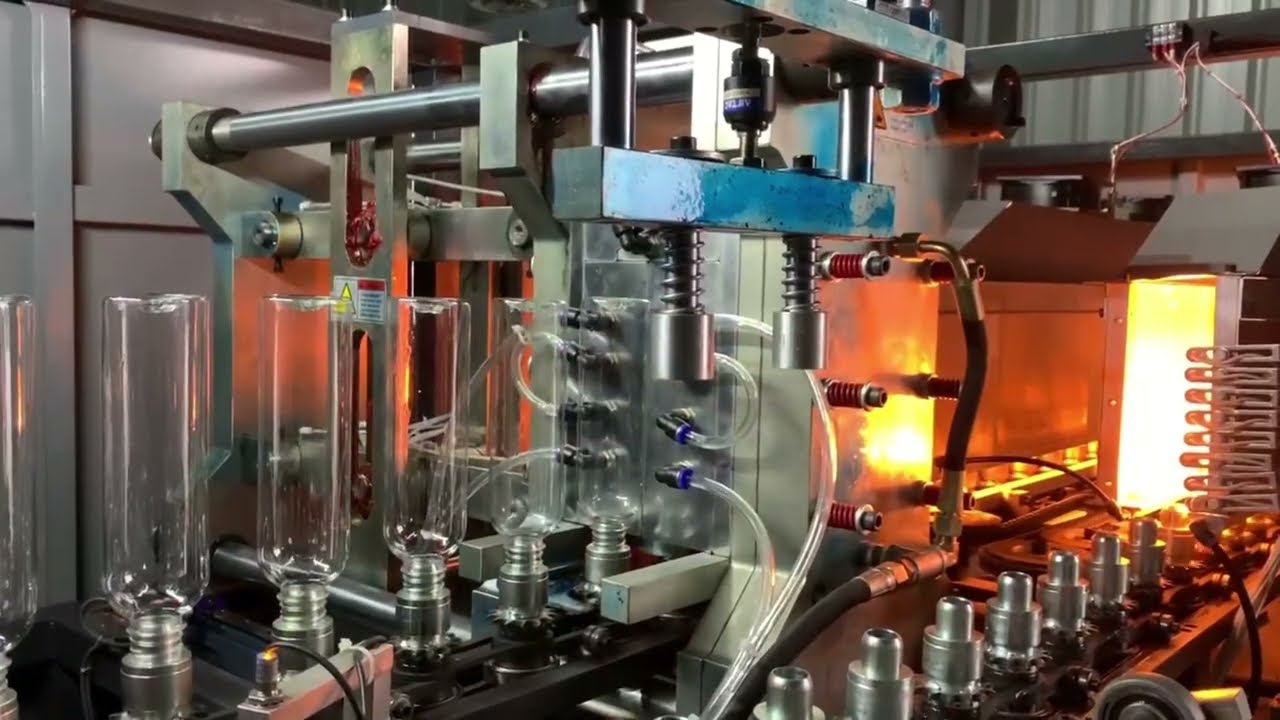

How Does It Work?

- 1 Preform heating in a special preform heater.

- 2 Opening of the blow mould (by closing unit) and insertion of the preform.

- 3 Closing of the blow mould.

- 4 Bottle stretching and blowing.

- 5 Opening of the mould and transport of the finished bottle to the exit conveyor.

- 6 Bottle prepared to transport.

Smart Moving Preform Unit

Automatic heating the preform to idea temperature, automatic sending preform to blowing plastic bottle

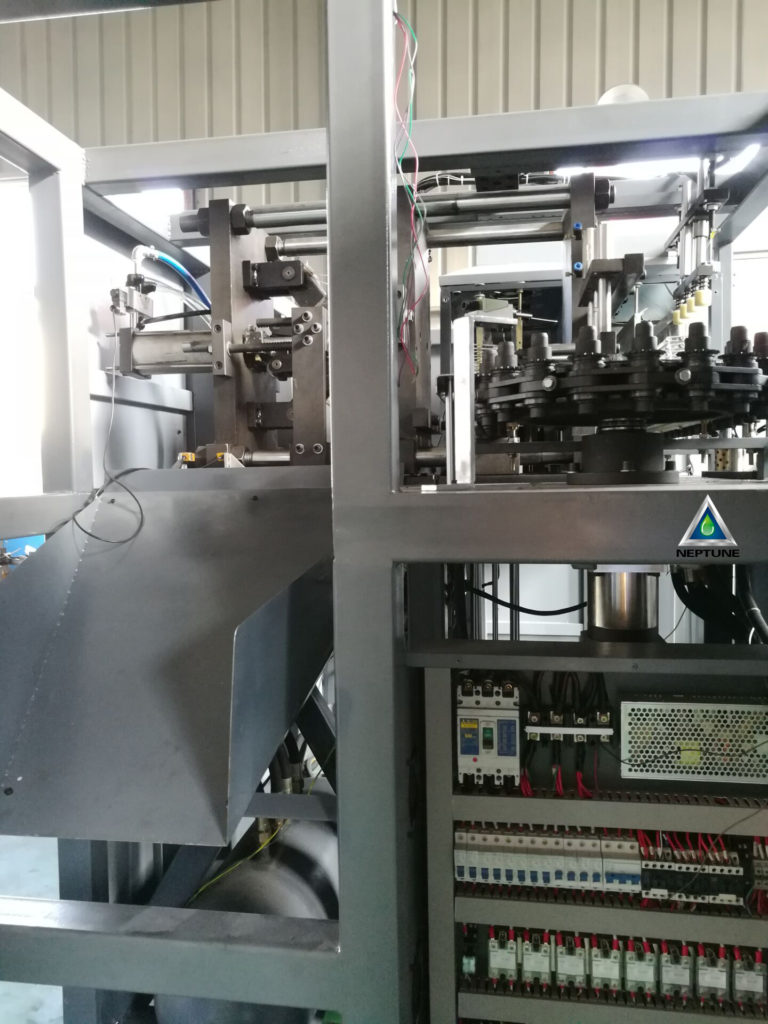

Clear And Nice Electricity Layout

Automatic conveyor the plastic bottle to air conveyor oulet system which can connection prefect with filling machine

Video of 2000bph pet bottle Blowing machine

Fall down outlet bottle way

It is just automatic fall down plastic bottle.

Air conveyor outlet bottle way

It can connect with air conveyor system so that easy conveyor plastic bottle to filling machine by air fan.