FOB PRICE:

$ 900.00

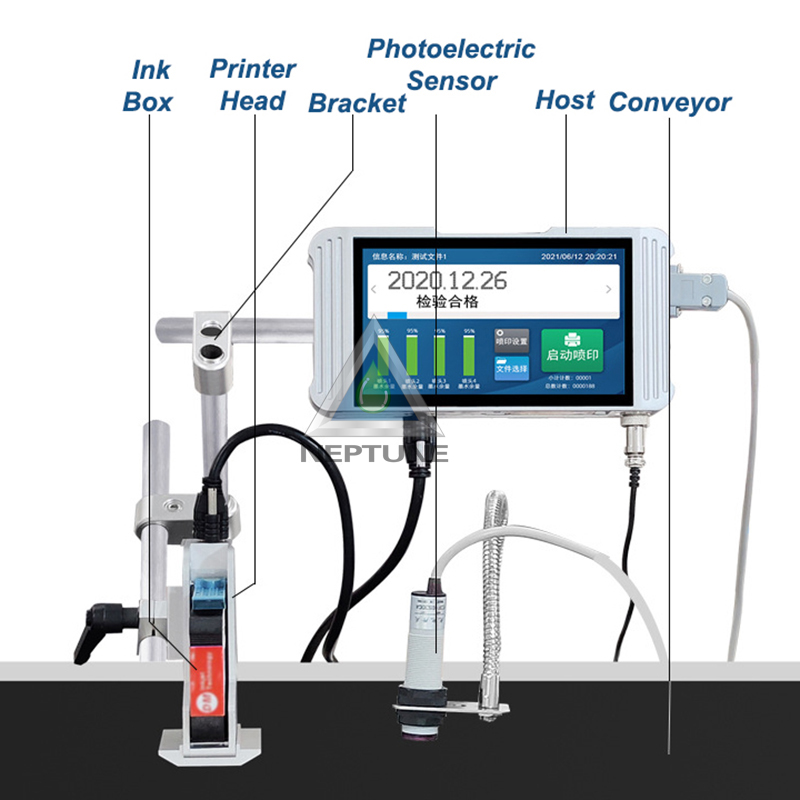

It is a very cheap time, code and words ink jet printer. Made use of thermal foaming technology.

Closed the goods printing will have a better performance. So it is better for printing content on the cap of the bottle water which is a plane. It can also printing content on the body of the bottle water. But it need requirement the printer-head very closed to the bottle water.

What is Thermal Foaming Printer?

The working principle of thermal foaming ink-jet printing technology is: using thin film resistors, the ink with a volume of less than 5uL is instantly heated to more than 300 degree in the ink-jet area, forming numerous tiny bubbles. The bubbles gather into large bubbles and expand at an extremely fast speed (less than 10 us), forcing ink droplets to spray out of the nozzle. After the bubble continues to grow for a few microseconds, it disappears back to the resistor. With the bubble disappearing, the ink in the nozzle will also retract. Then, due to the suction generated by the surface tension of the ink, new ink will be pulled to the ink ejection area to prepare for the next cycle of spray printing.

As the ink close to the nozzle is constantly heated and cooled, the accumulated temperature rises to 30~50 ℃, so the ink on the upper part of the ink cartridge needs to be used for circulating cooling. However, the ink in the entire ink cartridge will still be kept at 40~50 ℃ for a long time during printing. Since hot bubble ink-jet printing is carried out at a higher temperature, its ink must have low viscosity (about 1.5mPa. s) and high surface tension (about 40mN/m) to ensure continuous high-speed printing for a long time

parameter of the Water bottle Ink jet Printer

| Capacity of production | 6000 Bottles Per Hour |

| Languages | English, German, Spanish, French, Italian, Japanese, Chinese and else |

| Suitable for printng | text, label, digital, QR code, barcode, production date, time, logos etc |

| Printing size | 1-5 lines words or content for printing. Hight not over 12.7mm |

| Future change ink box cost | $ 50/ box |

| Printing content | Any date |

What Kind Of Content It Can Printing?

- It can printing different words with different fo

- It can printing black image or logo

- It can printing QR code on the bottle or goods

- It can printing 1-5 line different words or number mixer content

- It can printing anti-counterfeiting code on the bottle or goods.

- It can printing time on the goods

5line Printing content

It made use of TM12.7 MM printer head. It only can pringting 1 to 5 line words or number. It only can printing image or code not height tan 12.7mm

7 inch touch screen

Support your write by pen for different words you want.

Easy change ink box with printer-head

Every time the ink run out. Just need directly change another box ink with printer-mouth. It is very easy to change and do not need any professional.

What’s more, The ink box is very cheap. Just cost $50 per box. You can buy it from us or market with the setting model. It is HP company ink box.

Easy design and friendly use

Every unit is fixed and simple. It is very easy opretion and friendly use. More important. the equipment cost is very little.

It is need closed to goods.better printing on cap

The hot foaming ink jet printer invest small and good at small production plant use.

Compare the Thermal foaming ink jet printer advantage and dis-advantage?

Advantage

The hot foaming ink-jet printer ink drops is very smaller. Its printing ink drops frequency is higher. It can produce more richer harmonic colors and smoother mesh tones.

It meets the basic elements of low operating frequency, high nozzle number and single print resolution required for high-speed printing, which can improve printing speed and printer efficiency, and the integrated circuit technology can also continuously reduce printing costs.

In addition, because the ink cartridge and ink will generate pressure under the action of hot bubbles, the ink cartridge of thermal foaming ink-jet must form an integrated structure with the nozzle. When replacing the ink cartridge, the print head needs to be updated, so that users do not have to worry about the problem of clogging of the print head.

Dis-advantage

The nozzle with thermal foaming ink-jet printing technology has been working in high temperature and high pressure environment for a long time, and the nozzle corrosion is serious, at the same time, it is easy to cause ink droplet splash and nozzle blockage.

In terms of printing quality, due to the need to heat the ink during use, the ink is prone to chemical changes under high temperature, and its properties are unstable, so the authenticity of color will be affected to a certain extent; On the other hand, because ink is ejected through bubbles, the directivity and volume of ink droplets are not easy to control, and the edges of print lines are easy to be uneven, which affects the print quality to a certain extent.

In terms of application, because the thermal foaming ink-jet printing technology has certain restrictions on ink, only water based ink with high tension and low viscosity can be used, and organic solvent cannot be used. Therefore, solvent based ink cannot be used for outdoor large format advertising.